During the design process, we wanted to make Geronimo’s arm

as simple and as elegant as possible. Because of this, we decided that the arm

would consist of two parts:

- A parallel linkage oriented vertically so that the arms height could be adjusted

- A horizontally mounted arm that could rotate 180 degrees in order to account for the horizontal offset created by the parallel linkage

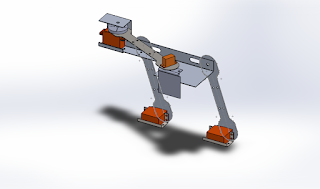

Initial prototype of Geronimo's arm.

Initially, we thought that we could use servo motors to

control the arm. Our first prototype proved that these movement patterns were

in fact possible using servo motors. However, there were some stability issues

with various components of the arm. Additionally, the catchment plate that the

pets were supposed to stick to changed orientation throughout the process,

which limited the arms functionality.

A second prototype was made, with new servo mounts for the

parallel linkage and a bracket for the horizontal arm. In order to maintain the

desired geometry of the catchment plate, a fourth servo was added to the end of

the horizontal arm.

Second prototype of Geronimo's Arm.

After the arms performance at time trials, we were concerned

that the servo motors were not powerful enough to remove the pets from the arm

using our chopping motion. A video of

this testing phase can be seen below.

Video showing second prototype's inability to remove pet.

In addition, the two servo motors controlling the parallel

linkage were not able to be precisely calibrated, and so one was always a few

degrees off from the other. Because of this, the servos would fight each other.

Eventually one of the servos “won”, and we had a servo fire.

The problems with the arm caused us to fall behind schedule,

and at this point, we decided that it would be in our best interest to start

from scratch and make our own servo motors. The arm rebuilt took Dave and I two

days, and involved us re-making the arm components to accommodate larger

motors, gear systems, and potentiometers.

Solid model of final arm design.

The day before the competition, we began to have problems

removing pets from the arm once more. We determined that the motor powering the

horizontal arm was not strong enough, and so we opted for a stronger motor.

However, when I was mounting the small gear to the motor we chose—something I

had done with every previous motor—I managed to break the motor. In the hours

that followed, the team searched for a replacement motor that would be strong

enough to accomplish the chopping motion we wanted. This set us back even

further.

We finally found a motor that suited our needs, and mounted

it to the arm at 10:30pm, the night before the competition.

The servos that we made featured the following:

- 3D printed bearings, to increase stability of the arms

- Potentiometers that rotated with the arms

- High torque motors

- Gear ratios of 3:1 for increased torque

The final arm design featured the following:

- An all-aluminum parallel linkage

- An aluminum horizontal arm

- A steel catchment plate attached via a zinc-coated steel hinge

- A magnetic sensor attached to the steel pin of the hinge to determine when the arm picked up a pet.

The final arm can be seen below.

Catchment plate and small servo mounted to end of horizontal arm.

Custom servo set-up driving horizontal arm. Nicknamed "Fat Bastard" by the team.

Custom servo set-up that drove the parallel linkage. Nicknamed "Satan" by the team.

Final arm design mounted on Geronimo.

Author: Josh Smith

No comments:

Post a Comment